LIRR Announces Completion of Third Track Project

West Babylon, NY – Early this October, New York Governor Kathy Hochul and the MTA celebrated the completion of the Long Island Rail Road’s (LIRR) Third Track project. The new 9.8-mile track runs from Floral Park to Hicksville, giving the railroad more operational flexibility to minimize service disruptions while improving safety and creating true bi-directional LIRR service.

This transformative work included several related projects including the construction of up to 5 parking garages, retaining walls, improvements to rail bridges and the removal of 7 street-level grade crossings. PRI is proud to have played a key role in several of the subprojects that helped complete the Third Track. Following is a breakdown of the work PRI completed for this extraordinary project.

Third Track SCADA

PRI designed, procured, fabricated, and integrated supervisory control system (SCS) cabinets into JCC as part of the Third Track project. The Nassau Supervisory Control System (NSCS) and Queens Supervisory Control System (QSCS) are part of a larger project that installs a mainline third track between Floral Park and Divide 1 Interlockings. During the installation of the third track, the existing supervisory systems at Nassau and Queens Towers were replaced by PRI and Railware with redundant Stratus Servers running Railware Dispatcher X. The new servers and operator workstations reside in the JCC building located adjacent to Jamaica Station.

The Railware software was designed with two stages to best integrate/update the new software into/with the old system. Stage 1 was to install the Dispatcher X software to control the existing Nassau and Queens territories. Stage 2 was to revise and add graphics to support the control and indication of the Mainline 3rd Track including the new Hitachi Microlok Microprocessors at Nassau 1, Nassau 2, Nassau 3, Park 1, Park 2, and Divide 1 Interlockings.

The Stage 2 design replaced the existing relay-based Nassau 1, Nassau 2, Nassau 3, Park 1, Park 2, and Divide Interlockings with a new Hitachi Microlok Microprocessor Interlocking. These new Microlok processors communicate to the Railware Servers at JCC and control the main portion of the mainline third track between Floral Park and Hicksville Stations. Stage 2 for Nassau 1, Nassau 2, Nassau 3, Park 1, Park 2, and Divide 1 Interlockings have been completed and are all now in-service.

Third Track Motor Generator Replacements

PRI furnished, tested, and installed three motor-generators (MGs) at the Floral Park, Mineola, and Hicksville substations. We were also tasked with replacing the MG control systems and power control rooms (PCRs) that house the MGs and their respective control systems for the Mineola and Hicksville substations. Our team also designed, tested, and installed SCADA cabinets for seven new traction power substation replacements and one mobile substation.

Third Track Signal Power Cases

PRI designed, furnished, and tested signal power cases to step signal power at 2400VAC down to 120VAC. In addition, we also provided EOSP control cabinets to operate electrically operated switches (EOs) either locally or remote. These EOSP control cabinets allow the railroad to open switches that sectionalize the track power at specific points as needed.

Third Track Pilot Wire

PRI provided pilot wire cabinets to assist with the cutover of new substations and their pilot wire circuits. The purpose of our pilot wire cabinets was to convert a breaker trip signal from copper to fiber optics and then back with the use of a PLC in each cabinet. This allowed the cutover of all new substations while maintaining seamless functionality between new and old systems. This was a temporary solution intended to keep the pilot wire functionality while the existing copper wire was removed, and all pilot wire communications were moved to the new Fiber Optic Backbone.

The new substations were designed to support both standard copper pilot communications and PLC-based pilot wire functionality. The copper was required to maintain connectivity to old substations; therefore, the new substations first connected to the network using a copper-based pilot wire system. The pilot wire conversion boxes and associated cutover plan allowed fiber optic communications to be used for standard copper-based pilot wire. The boxes simulated the remote partner and were transparent to existing substation operation. The boxes also acted as a switching point for communications to new and old substations during the cutover and burn-in processes.

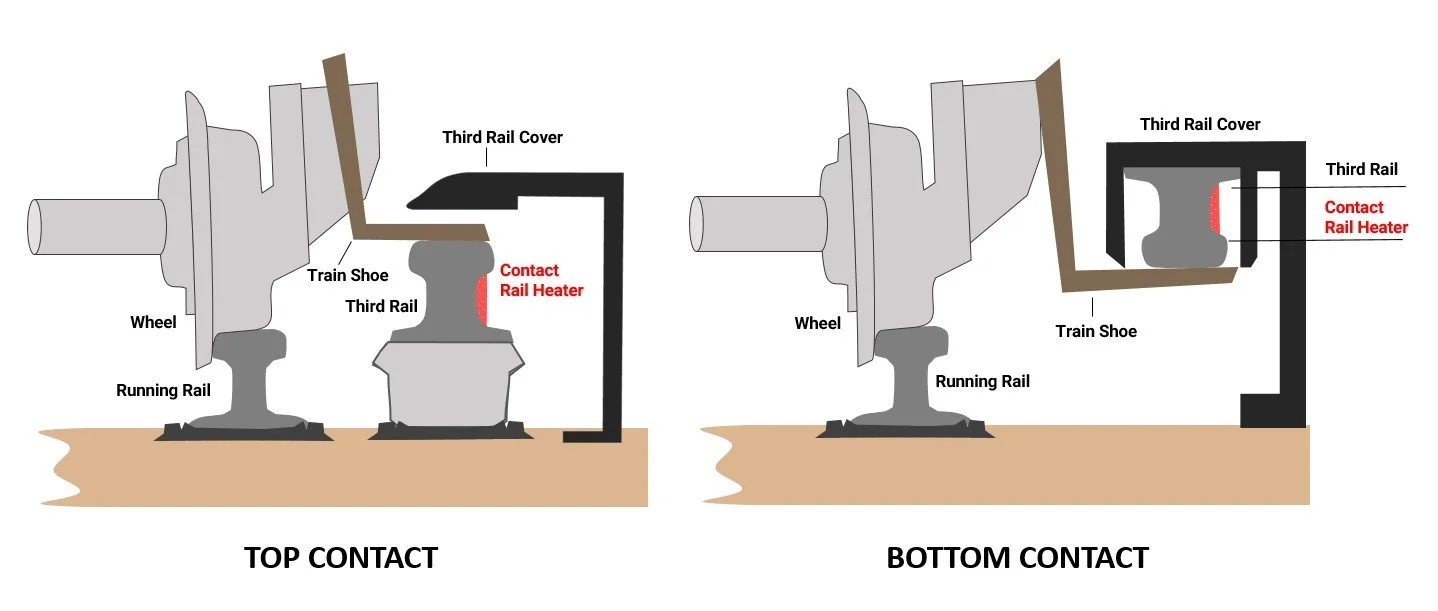

Third Track Third Rail Heating System

PRI partnered with EJ Electric, nVent, and Twinco on this project. PRI designed and fabricated 24 control cabinets, each going to 24 different locations along the new third track. Each cabinet houses a Siemens PLC and additional components to control the power of a heating system on the third track. Twinco provided PRI with a separate fuse box to house the fuses that are wired to each control cabinet.

PRI’s engineers also designed 56 contactor boxes, which are wired to each control cabinet. These contactor boxes control separate heating elements being controlled by each cabinet. PRI created a completely integrated third rail heater system in collaboration with nVent, which provided all the cables and rail clips and connected all these components together.